A while back, we visited the Soo Locks. When we came out of the locks, Nicole did her routine glance under the front of the van to look for "puddles".

It had rained pretty good while we were visiting the locks. However, there was something different about the spot that was near the front driver's side. It usually isn't there!

A sampling of it and we knew it wasn't water. A quick look under the hood revealed.... the Brake Master Cylinder was leaking where it joined with the Brake Booster.

This is what happens when we get Annie too close to her birthplace of Canada. She pees everywhere!

The reason that we are seemingly going backwards with this post is because we had to order a Brake Master Cylinder. After some thorough evaluations we realized that although Annie was making a mess and removing all of the paint from our booster, the booster itself was fully functioning and not taking on any fluid.

Since we were not in the mood to sit in the Soo Wally parking lot to wait for it we ordered one to pick up several stops down the road. By the time we had picked it up, we realized that we were also not in the mood to replace it just now, but instead just kept the fluid topped off as we drove along and held onto the new master until we reached a better location.

In this case, the location was while visiting with Darlene's youngest in Minnesota. She was conveniently located within walking distance of two auto parts stores and had a driveway in which we could park while working.

In truth, it is a very simple procedure. But we have learned, when your vehicle is 30 years old, most "simple" procedures almost always involve more than you had planned on.

First up... mark the line that goes in front (or back, depending on what matters to your personal remembering skills).

Then remove the lines from the Master Cylinder.

Take note that Brake Fluid is a powerful chemical when it comes to painted surfaces!

The plunger rod on the Brake Booster had seen better days. We contemplated cleaning it up. Then contemplated what the rod may look like inside the booster. Then ordered a new booster. After all, it is only four nuts and a cotter pin to take it off.

We waited two days for the booster to arrive. Meanwhile, we attempted to take the old booster off. While it is only four bolts and an easy to remove cotter, the bolts were very difficult to get to. We bought a new socket. Still no dice.

So, when the booster arrived and turned out to be the wrong one, we decided that the universe thought we should re-evaluate the situation. Upon application of the brake pedal, the plunger rod goes forward as expected and we could clearly see that the rusty situation stopped where the rubber gasket was. Inside it was clean as a whistle. So, we applied a little sandpapered elbow grease, checked the rod for integrity (it was solid) and that was that.

Now, surely, had we been in a different situation we would have wanted to either pull the booster to sand it down and paint it or at least do some sanding and painting while it was still on the vehicle. But, aesthetics were not our concern this time around and she'll hold for another little bit until we are once again in a position to make her pretty.

Turning our attention back to the Master Cylinder... Although it was functioning just fine, the gasket had seen better days. As had the C clamp that was rusted and brittle.

Nicole did manage to find a rebuild kit. However, the cost of shipping the kit was more than the cost of the kit itself. And, the overall total of a rebuild would essentially be the same as the purchase of a new cylinder but without the one year replacement. Since we'll be on the road for a bit more we decided to go with a new warrantied one and Nicole tucked the original away for dissection and a potential rebuild in the future.

We should mention here that when removing one of the brake lines from the original, it was discovered it had apparently been stripped upon installation. Bummer.

Despite her attempts to repair it using this cool tool she acquired from her Father, the nut was past hope.

So, it was time to learn how to double flare brake line and put new ends on it. Yes, that was a plural end(s). Upon removing the other end we discovered it had fused itself to the proportioning valve.

Flaring Tool Kit Free Rental from Oreilly's!

Doesn't look too bad for Nicole's first ever double flare.

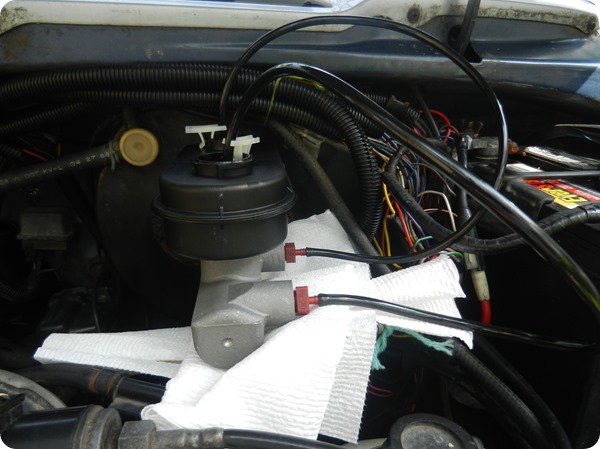

Next up, mount the master and bleed it.

NOTE: although we mounted the master on the van we are still doing the required bench bleed. We are simply using the mounting bolts as the vice that we did not have and using gentle brake pedal pressure instead of a screwdriver to manipulate the plunger.

The black tubes run from the ports on the side (red plugs) back into the master itself. So the fluid is only circulating through the master. Each time we pumped the pedal the air (that you don't want) inside the master was slowly replaced with fluid. A few cycles of pumping and re-filling and the bench bleeding of the master was complete.

Next up, reattach the lines. Simple enough.

In the event that you are not familiar, brake fluid is typically clear as water.

So, instead of simply bleeding the air out of the lines, we decided to also remove all of the old fluid and replace it with new.

A little backwoods ingenuity and it is "Out with the old" accomplished easily and with no mess.

All back together and she was working like a dream.

To answer that question we wrote under one of the photos above regarding Nicole's first attempt at double flaring lines...

"Will it do?" Well, yes, it will 'do'.

However, we have observed that both ends are leaking every so slightly and tightening is not the issue. Instead, a bit more research revealed that she flared them a little too (good) much. Apparently, in double flaring, you are to not over do the second flare so that when you tighten the flare over the port it will conform of its own choosing.

Either way, we have a new, non-leaking master so the booster is no longer suffering and the slight weeping we are getting from the nuts never even makes it off the line before it evaporates.

And, last but not least, even on our multiple walks to the auto stores nature was a part of the journey...

We discovered this beautiful new-to-us caterpillar in a parking lot on our walks. This is Hyalophora Cecropia - the Cercropia Silkmoth Caterpillar.

Unfortunately, he appeared to have expired. Nicole had not brought her camera with her and wanted a shot for her collection, so we placed him on a piece of bark and carried him home. After his modeling shoot, we laid him in the grass just outside the apartment door and for three days there was no change. Then one day, Nicole and Darlene are working on the van when Lisa comes running around the corner, "He's alive! He's alive!"

We couldn't believe it. He was indeed moving. However, it appeared that only the front part of his body was working. Either way, we went out and collect many variety of leaves and provided a feast for him; even made several attempts at hand feeding. After several days though there was no change. He was still moving only his head and thoracic legs. The conclusion was that he had been parasitized (which also paralyzes).

So, we placed him back outside in the grass with his collection of food and let him be.

At this point in our journey we were running a bit late for a required date. It was time to hit the road...