And so we pick up where we left off…

The wall and ceiling insulation are up and the floor is down. It is time to start planning for the walls and to get started on the refurbishing of the original cabinetry and bench seats.

Oh… but in between all of that Nicole decided that instead of purchasing new non-slip rubber mat to put in the entry doorway (old one was torn up) she would make her own non-slip surface with things we already had.

Taped up, sanded and primed.

A few coats of Rustoleum with sand thrown in makes for a durable texture.

The Before (above photo) and The After (next photo)

Close up of the final texture. You can make it as rough (or otherwise) as you would like by putting extra coats of paint (with no sand) on top of your final layer of sand.

We’ve been very happy with the results. Very durable, non-slip surface that is easily washed down. Perhaps the only negative would be that a rag or brush is necessary if you get something on it that needs scrubbing since paper towels can shred on the texture. But, for small dirty spots a little water and dabbing a paper towel have worked just fine.

Oh and while we are on the subject, we had some carpet padding left over from our home renovations and used that for the front of the van until such time we could decide what we wanted to do in that area. It’s been great for a whole year. Sweep-able and obviously can’t take a whole lot of abuse but it was just sitting in the garage and the garage was getting sold with the house. They say you can’t take it with you… but, if you put it in your van and drive off, you can!

Oh, and having now lived in the van for a year with this for our front flooring we’ve decided that we will at some point paint this area with our favorite Rustoleum brand paint and then place some mats under each foot area for temperature control. Again, easy care and management are primary objectives. With the engine of the van literally right between the driver’s legs and the passengers legs things heat up quite a bit. The use of a heat resistant paint is a consideration but not financially prudent at this time. We’ll also at some point re-do the underside of the doghouse and create a few more heat shields around the engine. But those projects go in the ‘Exterior Renovations’ file.

OK… so on to the walls.

Well, almost on to the walls…

Before we could put up the walls we needed to figure out how we would frame up the windows. We are aware that many people who renovate vans with the intent of living in them prefer to cover up the windows for either stealth reasons or to provide them with more wall and thus cabinet space. This was not an option for us. One of our biggest draws to the van was all of the light from the windows and the amazing nearly 360 degree view they provided of our environment. Since we were not using the original design of ‘floating’ walls and windows that were trimmed out with plastic, it was important to frame the windows to match the depth and curve of the van’s internal ribs. Here’s what we came up with.

Well that’s the sides, top and bottom for two of the five windows.

We decided to paint the window frames with (surprise!) black Rustoleum.

Before (above) and After (below)

It was difficult to get a good shot to truly show you the line of the new frames with the ribs but here’s a reasonable one. It was more obvious once the walls were put into place.

And, yes, we had to re-cut our pink insulation to fit around the larger window openings. This all worked in with our desire to get as much out of our windows as possible. The original design closed them in right around the frame. Our design gave us a much more open feel that made the windows and the view feel larger.

Finally… the walls!

We used a basic Lauan with some poly coats on it for all of our new wood surfaces. The Lauan was flexible enough to withstand the curve we wanted to obtain and the poly turned them into a resistant and easy to clean surface.

We primarily used the vans original ribbing to secure our walls but where that was not possible (example in the above shot we were meeting two boards together on one rib) we curved some blocks of wood and attached them to the rib to increase surface area of attachment points.

Knowing that we were not going to cover our screws, their placement was painstakingly mapped out in a symmetrical and eye-pleasing orientation.

On to the cabinets…

We knew that we were going to keep the framework of the original upper cabinets and bench seats but needed to get rid of the 1988 paneling that was flaking and peeling. There were also some unwanted access doors and holes in them from things we were not planning on keeping (like the rear AC unit). So, we stripped them down to their basics and created new coverings.

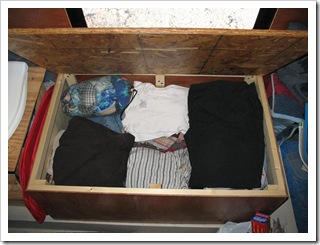

Bench Seat Before

During

After

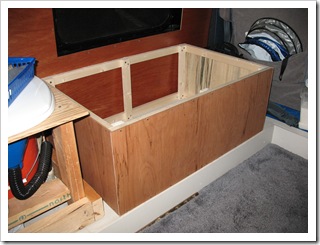

Our new design for the van meant that we had room for one more small upper cabinet on the driver’s side (which was where we were relocating the sink). So we put our framing skills to work and created one. Original cabinet on the left and our homemade version on the right.

The old cabinets were primarily supported by the floor to ceiling walls that we were not planning to replace. The fiberglass hi-top had support ribs that could be screwed into but the only one that matched up with the depth of the cabinets was in the rear of the cabinet. So, we got creative.

This ‘tray’ was left when they cut the van top off to put on the hi-top. It made a great channel for runs of wires and (after we made these angled pieces) made a great lower attachment point for the cabinets. As mentioned previously, we knew that the van was going to shake and shimmy and that, since we had eliminated the floor to ceiling stability of the previous design, our cabinets were going to rock and roll, for sure! So, we came up with this super stable option for the top attachments.

A view of the support beam before and after installation.

And the left and right cabinets all secured into place. Eventually we got those hanging lights back in place too. Although LED lighting is a choice for most folks these days, we are not big power users. The rig also came with a bunch of spare light bulbs. Thus, continued use of the original lighting made more sense for now.

We decided to keep the original oak cabinet doors but removed the paneling from the center. We also sanded their yellowish color down then added some stain and poly. A year later we still have not come up with a final concept for what we want to replace the paneling with. To be honest, it isn’t on our ‘important’ list. It is easy to get most things now without opening the cabinets and the lip from the door keeps things from falling out when driving.

Well, surely we are over our photo limit for this post so we’ll send it off to be published. Keep your eyes peeled for continued posts to get you up to date on where we currently are with interior campervan remodeling projects.