We've suspected for a few years now that we had a leak or two and then some in our exhaust system. Since it is all original, it was to be expected. Spending more time riding the bikes and less time driving Annie however confirmed for Nicole's nose that it was time to find them.

Driving Annie only a few times a month has made the smell of exhaust on our clothing more obvious than it was when we were in her every day. Exhaust on our clothing means our exhaust system is not just leaking it is finding its way into the van as well. And, that is not good.

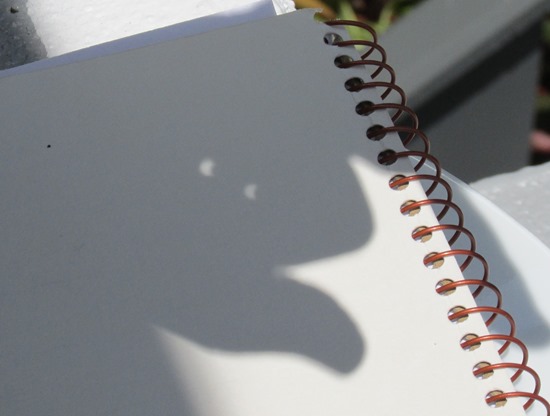

We went high tech for this job.

Shop-vac on reverse, a rag to fill the gaps, packing tape to hold it all together and soapy water.

Nicole has been watching this hole for a while now. It is near the rear of the van so she hadn't been too worried about. It was a good place to start however when it came to seeing how easy it would be to feel the air blowing out of any cracks or holes. In the case of this one... very easy!

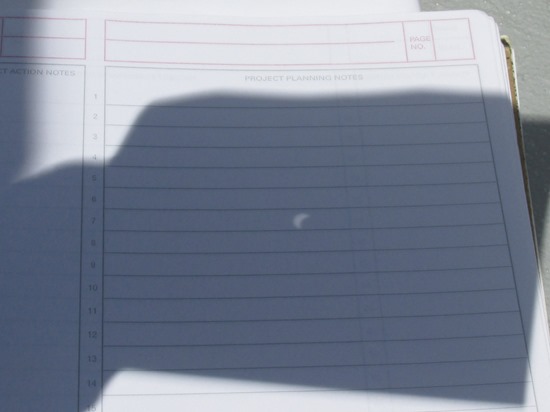

Working forward with a spray bottle full of soapy water in hand, this split in the seam of the muffler announced itself with a nice big bubble.

As did one in the weld just after the catalytic converter.

And one on the topside just before the cat.

We had expected that if we had leaks along the pipe run that they would be at the weld points as that is a common point of weakness.

Our pre-cat (also known as a mini-ox converter) has a leak at one of the welds too.

Now to the engine bay and the things we already knew about...

When we bought Annie we knew that one of the air injection crossover tube attachment bolts had broken off inside the manifold. So, we've been patching that for a while now with RTV. With the RTV pulled away the gap is more obvious and without a gasket and a bolt to tighten it down there is a significant leak at this point.

We were surprised however to find on the driver's side of the engine that despite having a solid bolt down connection the same area was leaking, as well.

Not sure if we will finally bite the bullet and work on getting that broken off bolt on the other side out so that we can remove the crossover and put new gaskets on both sides or just patch this again. Either way, these two points definitely need to be sealed up.

Unfortunately, not being able to find a replacement bearing, our smog pump re-build did not hold up as long as we would have liked. So, we have been driving with the hose system disconnected from the check valves and have gone through many ideas of covering them to keep exhaust from leaking out.

They hold pretty well for the most part but we have to keep replacing them when they spring leaks. A more permanent solution for these two points is in the works until such time that the air pump can be re-installed.

Our power heat riser valve assembly has a leak at the point in the center of the photo.

Lastly, although our manifolds themselves are solid and sans leaks, the center gaskets on both sides are leaking on the underside.

And, that is what we found. It sounds like a lot but it wasn't more than expected. Welds are common leak points as are gaskets. The holes we found are small so we are currently exploring options for patching these leaks. While doing things like removing the manifolds and putting new gaskets on might would make more sense to some, the fact that ours have been in place for almost 29 years means that removing them has the potential to do more harm than good. We aren't in the position right now for something like that to go wrong. So, we'll patch to keep things running smoothly and exhaust leak free for now.

That's the latest from down south... on Annie.