Guess it is pretty obvious, since we said that we were leaving Sevilleta, that Nicole finally figured out what Annie was trying to say all of this time.

Let’s see, previous to this post we covered the fact that the electrical components of the starting system had been dissected, cleaned, individually tested and found to be a-o.k. We also covered the fact that Nicole had removed the starter, tested its components and cleaned it up which although it resulted in a great first start was apparently not the answer to the ongoing issue.

That brings us (first) back to the starter. After Nicole put the starter back in she heard from one of her vannin buddies who had been away and was delayed in responding to photos she had posted. He indicated that a part of the starter she neglected to put an great deal of focus on (cleaning wise) was one of the most important. A little more research about starters and Nicole understood why. This meant that the starter was coming off yet again and this time the sole focus was on cleaning up the seriously pitted solenoid plunger and contacts. While these are parts that you can replace rather cheaply, it only seems right to first try to clean them since you have to open the starter up either way and cleaning is after all... FREE.

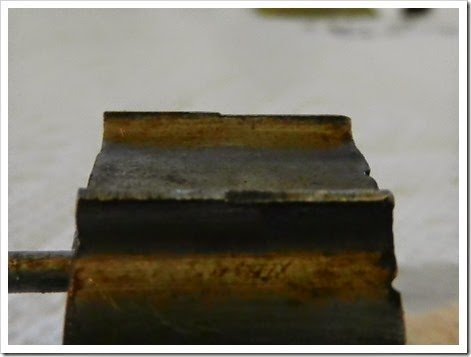

The Before... You may remember the condition of the plunger and contacts.

Although we had seen worse, they certainly were not conducting as well as they could.

The After... Smooth and Shiny.

These surfaces are ready to send some solid current.

Since she had it open again, Nicole went ahead and addressed one other thing she had previously let slide. She went ahead and cleaned out all of the old grease from around the gears and lubed them with new.

So, starter solenoid and contacts cleaned and ready it was re-installed and the van fired right up! Of course, she did. She loves when we give her attention. This however still did not solve our starting problems and they quickly returned.

That is when Nicole went into Voltage Drop testing. This is some super cool and easy voltmeter testing that you can do to see if a cable, wire or other connection is ‘dropping’ voltage and therefore decreasing available voltage to specific parts. No photos but also no real significant findings. That’s a good thing on one hand. On the other, it was back to the drawing board. Oh, in the mix here somewhere new spark plugs were installed too.

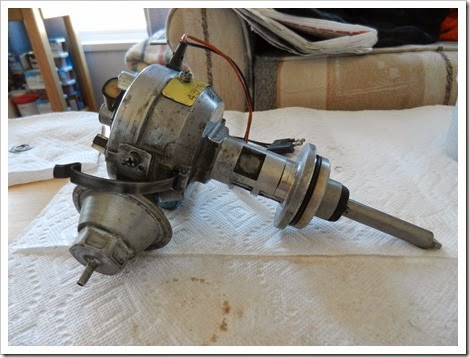

At this point, attention turned toward the distributor. Although cap and rotor replacement are a regular part of vehicle maintenance, ours were only a few years old and still looked and tested just fine. The gap on the pick-ups could have used a little better set but it has never been a ‘primary’ problem set the way that it is and something made them difficult to adjust anyway. Having tried everything else, the guys on the van forum suggested Nicole delve deeper into the inner workings of the distributor.

She found a lot of things that could use some help but they weren’t the cause of the new problems.

The shaft for example could use a good cleaning.

It was discovered that the bushings between the two plates were unevenly worn which caused the top (pick-up) plate to sit off level thus making the pick-ups difficult to set

and causing uneven wear on the reluctor.

Although these things weren’t causing the actual starting problems it couldn’t hurt to do a little fix’er up while it was apart. Nicole figured out a way to shim the two plates so that they still moved as they should but now they sat level. She then gently filed the reluctor teeth down so each was once again a straight surface. Put back together the pick-ups were now able to be set to their very tiny gaps of .006” and .008” from the reluctor.

Sure, these things would make the distributor work better but they weren’t the problem. Time to dig deeper.

Below the plates Nicole discovered one big pile of rust.

These are the weights and the cam that operate the mechanical advance in the distributor which in turn affects all sorts of important things like timing for one. The cam, which is the first rusted part from the top (shaped like an upside down T) is supposed to move independently of the shaft. It didn’t. The weights which are the things below the cam were supposed to swing out and in based on cam action. Although they could be manually moved out they didn’t return on their own and since the cam wasn’t spinning independently based on rpms, the weights were generally not moving as they should.

A little elbow grease and regular grease (to lube them after reassembly) and things were moving and behaving as they should.

Let’s see that before photo again...

And the after...

with a little cleaning, filing, leveling, sanding and greasing then...

back in the van it went.

Fingers, toes and eyes crossed and breath held, Annie fired up like a champ. Sure, she always fires up the first time after we mess around with her. However, it has been a little over five weeks and she is still starting really well. We’ve also noticed better hill climbing and high rpm acceleration with the now working as it should mechanical advance.

And THAT (for the time being) is how Nicole cured what was ailing Annie.