Working on the van is a breeze after learning how to tear out a load bearing wall in the house and re-frame to put a big twin-double-hung window where there wasn’t one before. About the only thing that we have to think about in the van that we didn’t in the house is that it moves and shakes and then moves and shakes some more. This means that everything we build or wire must take this into consideration.

We made a point during re-build to plug all old screw holes and create new ones and thus far we have not been sorry. Our original door panels, which are still in use until such time we come up with our final design, are the only things that loosen or lose their screws on a regular basis.

We made the decision to completely re-wire the entire RV section of the van for two reasons. 1) The original wiring was quite a web of poorly labeled and crazily run confusion linked with 1988 connectors that did not even stay shut anymore. 2) Doing it from the ground up allowed us to minimize the wire runs and create a system that was well labeled, easily traced or re-run and completely visible by simply opening cabinet doors or raising the top of the bench seat. All of our new wire connections are nutted and then very well taped.

You think we were kidding?! This was after some organizing.

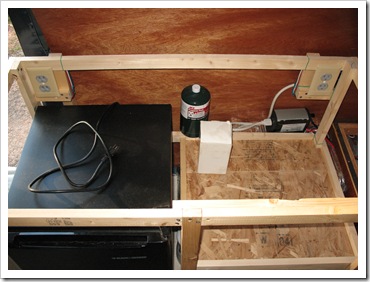

So much neater now and about 1/3 of the original amount of wire and each wire clearly labeled with where it goes or comes from. Since this photo was taken we’ve added two 110 outlets under our kitchen counter that run directly off of shore power and created a connection to charge our batteries from our converter now and then.

Our small Cobra inverter sits behind on the wheel well and is connected directly to our two 12 volt marine batteries. The white cord is a surge protector that we switch from the inverter to one of the outlets depending on whether we are running shore or battery power. The original design of the unit had the same number of lights, outlets (including two twelve volts) and a generator. We’ve removed the generator and installed solar. Other than our solar, which has been clearly laid out in a previous post, that is the gist of our electrical. At some point we may re-hook our water pump. The wiring is already in place for when / if that day comes.

Although the campervan’s interior was overall in good condition when we bought it there were a few things that showed her age. Things like the carpet (which was sufficiently dirty, especially that which surrounded the toilet and begged the question why???), the headliner material on the ceilings and walls had deteriorated and was virtually dust behind cloth, the plastic window shrouds were cracked and fragile and the paneling was also slowly succumbing to the years.

The man we bought the camper from had been letting his grandsons use it as a playhouse so the carpet around the toilet definitely had seen its share of things we didn’t want to carry down the road with us.

Despite being a complete campervan, Annie was intended more for a weekend full-hookup outing and not meant for full-time boondocking off the grid living. This meant… there was absolutely no insulation. After much research and consideration we decided that, although we wanted insulation, our intent was to be mobile and that mobility meant we had the option to escape temperatures that just were not bearable. We also realized after an unbelievably warm trip to the beach in Florida with the van fully stripped down to just a metal box that the key was going to be creating an air circulation gap between the exterior metal and whatever walls we put in. Taking all of that into consideration, we opted for some insulation over none and were not concerned with major R-values or similar factors.

Our choice was these wonderfully easy to cut and flexible panels and we have not be disappointed with this option. For the floors we considered insulation under plywood and then decided that the plywood itself with a few throw rugs over it in the super cold would be just fine. First to patch, prime and paint with a cool color.

In tearing up the carpet we discovered the source of the constant gasoline smell in the van was not the carburetor or malfunctioning emissions system. It was that two of the screws holding down the original flooring went into the top of the plastic gas tank. We then discovered that many of the screws placed to hold the flooring were randomly shot into locations that may or may not have held a gas line, black tank, electrical wire, etc. So, we carefully removed each screw and from underneath traced everything to ensure that no more damage had been done in the original installation. We filled all of the original holes, sanded any pre- or obvious rust areas and spot primed and painted over them. Then we went through and placed all of our new floor screws only in locations that we could observe from underneath the van. This also allowed us to easily put some putty around them too. By stripping the van down to the base we were able to fill any hole to the outside that would not otherwise be used. Thus, also eliminating potential entry points for critters.

Along the lines of holes that needed to be plugged, we had decided that we would get rid of the water flush toilet that came with the rig and put in a ‘urine separating’ toilet seat over a bagged bucket with (our choice of) pet bedding. It takes a bit of aim (er, getting used to) but we are very happy with this decision.

As a result we needed to plug the sewer hole that led to the black tank.

Shuffling through the garage we found two perfect items for the job. The first is already glued and caulked into the hole upside down. Can you tell what it is?

That’s right, a kitchen sink garbage disposal plug. After that cured we cut a section of milk jug and secured that over the hole in the metal flooring. The black tank hangs about 1/2” below the actual metal flooring so in the event that our original plug came loose and liquid started trying to escape, it still would not make it into the van and neither would the smell thanks to the milk jug cover. We also made a point to put a separate board down in this area so that we could pull it up if needed without affecting other sections of the van.

There was another hole into the black tank that led from the sink. Although we still aren’t sure that we want a sink in the van, this inlet allowed us to easily tube #1 from our new toilet into the tank. In the event that we do hook up our sink we will simply place a ‘Y’ connecter at this tank entry point.

Above is our temporary toilet framework made in a pinch for a weekend trip.

It hasn’t fallen apart and fits perfectly into our design so we’re still using it.

Plywood down, we toyed with the idea of sticky tiles or linoleum or click-n-lock flooring. None of these fit with our idea of minimalism combined with easy clean up and most importantly, no concern with damage due to everyday use. So, we went into the garage and grabbed a $5 ‘oops’ can of Home Depots best Exterior Paint that had been sitting around. Several coats later we were quite pleased.

We liked it so much that we decided to do our ceiling in it too. The beauty is that sweeping is a breeze, it easily washes up with soap and water and if it starts showing its age or we ever get tired of it we can change it out for $5.

Before putting our ceiling up we made the decision to use Reflectix on our hightop. There were several reasons for this but the most important was that it was the thinnest material we could find that would at least give us some barrier between the exterior and interior surfaces. We also wanted to preserve as much cabinet space and headroom as we could.

Somewhat complete ceiling. We also decided to paint the exterior hi-top white instead of the dark blue that it came with and that cooled things down considerably. However, we are not huge fans of the white (RV’ish look) on the van and will sometime in the future change all or at least the sides of it to a silver to match the rest of the van graphics.

Looks like the state of our current internet is going to limit this post here so we’ll stop here for now. Stay tuned as we get into framing up the windows, making walls and refurbishing the cabinetry.