We interrupt this travel blog for a bit of detail on necessary maintenance projects that help to keep our trusty steed going strong.

During a peek here and there one day Nicole noticed a new leak.

It was assumed to be coming from the differential plug so a new plug was promptly popped in to test the assumption. After a few weeks the diff was still dry and it was confirmed that the plug had indeed been leaking.

While switching the plugs, Nicole did the recommended quick finger-dip test to check the fluid level and found it to be low, thick and very dark. So, a decision had to be made to either top off the very dirty fluid with a little new or to tackle the job of removing the cover, draining the old fluid and replacing the cover with a new gasket and new fluid.

After a bit of consideration and the purchase of a sweet new extendable handled, pivoting head ratchet to make the tight spaced job easier, off came the cover and out came the fluid.

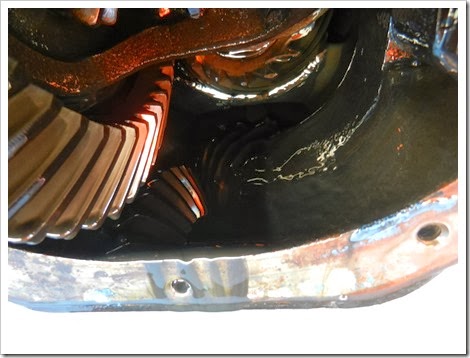

Both the cover and the fluid were a mess! The RTV gasket the previous adventurer had created was not only thicker than Fort Knox but had littered the oil.

The good news was that there was not much found in the way of metal shavings.

Thick black sludge would be in the ‘What You Don’t Want’ category.

The inside of the cover could use some attention and the topside of the cover, coated in a layer of rust, had also seen better days.

A clue to how much gasket maker was used last time could be seen here.

The top of the bolt wears a blue, RTV hat as tall as the bolt itself!

The identifier tags were finally readable once they had been cleaned.

For the most part, the gears were looking pretty good for 25 years of use.

The nicks in the apex of the gears did not appear to be within the range of the contact surfaces so not so sure what caused them or if they are a product of manufacturing.

A little attention to the inside of the cover.

Primer and paint to the topside.

Clean up the bolts, the mating surface of the differential housing, add a (paper) gasket, refill the fluid and she’s all back together.

This is the nicest looking part on the underside of the van. Let’s see how long it stays that way! Most important, familiarity with the differential has been achieved and Annie is now spinning her gears through clean fluid.

In the area of slight leaks… most of the original rubber grommets or seals have hardened and shrunk over time. This is typical with age and the high temperatures that they are subject to. So, Nicole has also started a process of replacing them one at a time. First was the PCV valve grommet (note to self: next time you have the valve covers off to put on new gaskets… go ahead and replace the grommets because they are a lot easier to do then). The PCV valve grommet was hard as a rock and it isn’t easy to get a rock out of a tight spot. But there was success, eventually.

Next followed the oil fill tube grommet. Again… hard as a rock and quite a process to remove while ensuring that none of the small pieces fell into the valve area.

Success came in many pieces. However, the replacement part that the auto parts store computer said was correct… was not correct. So, with a gaping hole just waiting to spew oil and a 120 mile round trip to the nearest auto parts store, some creativity was required.

An item that was easy to cut and shape which could also handle the high engine temperatures that our Annie puts out was needed.

Enter… the bottom of a pie plate (you can still see the knife marks). Sure are glad that we decided to treat ourselves to that key lime pie the last time we were in town! A little RTV a good ways from the opening (so that none would slip into the valve area) and we were all sealed up and drivable.

This time, we did our own research and discovered that there was a part that was correct but it was labeled with the wrong name.

This says ‘PCV Grommet’ but it is the exact right part for our oil fill tube (it is also the same part that our breather uses). For the record, the PCV Grommet for our van is 1/4 the size of this so we’re pretty sure it’s a mislabel.

A perfect fit (pre-oil fill tube insert). We lubed the tube with a bit of oil to put it back into place, she was back together in no time and the valve cover is no longer covered in oil after driving.

We have been trying to replace each rubber grommet as we notice them finally giving in to the signs of aging (pretty easy to see when a small bit of liquid starts coming out around them).

Next on the list are the two covers for our brake master cylinder. We’re noticing quite a bit of leakage around them lately. Seems a good idea to not let that level get too low!

Since we take these off before each major drive to check the fluid level we know it will be one of the simplest replacements yet!

Well… that’s the latest in the maintenance department. It isn’t raining today and the temps have made it to 50 so we’re off to explore.